The geometry of the wheel angles relative to the body and the ground plane is one of the most important factors car driving safety. When designing, the camber, toe and caster angles are always set at the factory, otherwise the vehicle's handling on the road may deteriorate significantly.

Why do you need to do a wheel alignment?

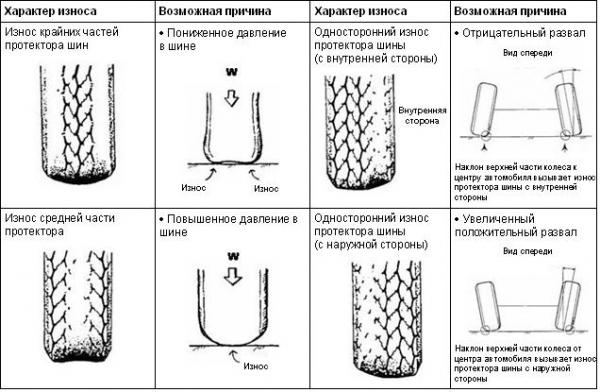

Wheel alignment must be done in any case, since incorrect installation or its complete absence leads to very rapid wear of the tires and deterioration of vehicle controllability. Camber is the angle of the wheels to the road. Depending on the needs of the motorist, it can be either positive or negative. In the first case, the upper part of the wheel is tilted towards the center of the car by about 1.5 - 2 degrees. This camber is not desirable as it increases tire wear, but it also provides better traction. In most cases, positive camber is set.

Toe-in is the difference in distance, which is measured along the front and rear points of the wheels (discs) horizontally. It is measured in millimeters or degrees. It can also be positive. Negative and zero. Positive toe-in of the front wheels provides stable control at high speeds, but at the same time maneuverability, that is, turning, deteriorates. If the toe is negative, then it is easier to drive the car, since the reaction of the wheels to the rotation of the steering wheel improves. However, in this case, you will have to change the tires often, since they wear out very quickly on damaged roads. For rear wheels the situation is almost the same. The most the best option the wheel toe will be set to zero. This will keep both handling and tire longevity in balance. Normal wheel geometry angles provide the vehicle with fuel efficiency, more easy control and agility, stability and reduced susceptibility to shock absorption and rollover.

It is also important to know the first signs of an unadjusted wheel alignment:

- The car drives to the right or left;

- Elevated and uneven wear tires;

- The need to replace steering and chassis parts.

If you have any of the above problems, then it would be best to immediately contact a car service center, where special stand You will be given the necessary adjustments to the geometry angles. A modern stand is capable of performing the necessary measurements and adjustments. The service center will provide you with a report on the work performed, it will contain the following items:

- Camber angles of the left and right wheels for both suspensions (front and rear);

- Toe angles (also for all wheels and both suspensions);

- Offset of vehicle axles;

- Rear axle rotation;

- Transverse and longitudinal angles tilt of the rotation axis.

Before starting work, the technician inspects the car for faults, measures the tire pressure (it should be the same) and then adjusts the angles.

Do-it-yourself camber adjustment

Adjusting the angles can also be done at home, especially since not all car services have computerized stands. Therefore, if you have repair skills and a certain dexterity, then you can perform camber adjustment yourself and not overpay money at a car service center.

Before starting work, you need to prepare necessary tools and car platform.

First, we will need a telescopic ruler, a cord with a plumb line at the end, chalk and driving tools. The machine must be placed on a level area, preferably with an inspection hole.

The first step is to install the machine on flat surface and make chalk marks on outside wheels at the top and bottom of the tire.

Next, attach a piece of cord with a plumb line to the car fender so that it and the marks on the wheels are in the same plane. Then the distance is measured from the cord to the top mark, and then to the bottom, you need to measure along its far part (edge). In this case, the difference should not be more than 3 mm.

At the third stage, you need to turn the wheels 90 degrees, rolling them a little, after that we put two more marks and take measurements. Then we turn the wheel 180 degrees and perform similar operations to the previous ones.

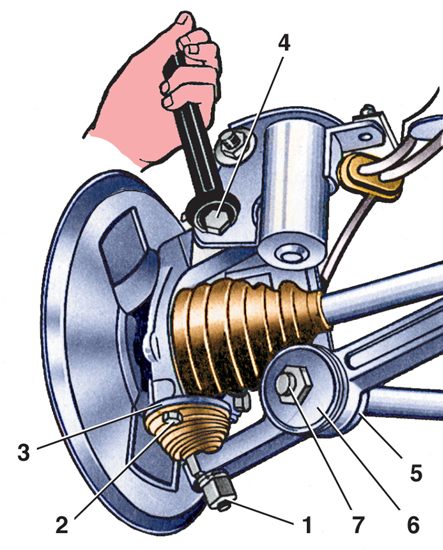

After taking measurements, the car wheel is removed and the bolts that connect the shock absorber bracket to the swivel fist, which noticeably shifts to the right side to the required distance according to measurements.

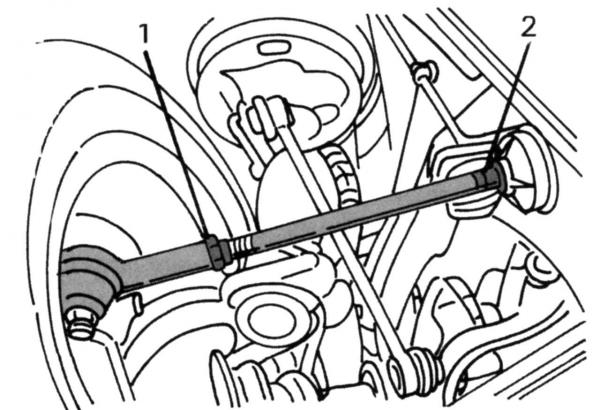

To do this, you need to apply marks already on inside wheels and support telescopic ruler to these marks. We combine the fixed pointer on the ruler with zero and turn the wheels a little forward, after which we take measurements again. If the results show that the front of the tire is larger than the rear, then the tie rods are lengthened slightly. If it’s the other way around, they shorten.

You need to understand that correctly set camber and toe angles make the car more stable on the road and significantly increase the service life of the tires and suspension.